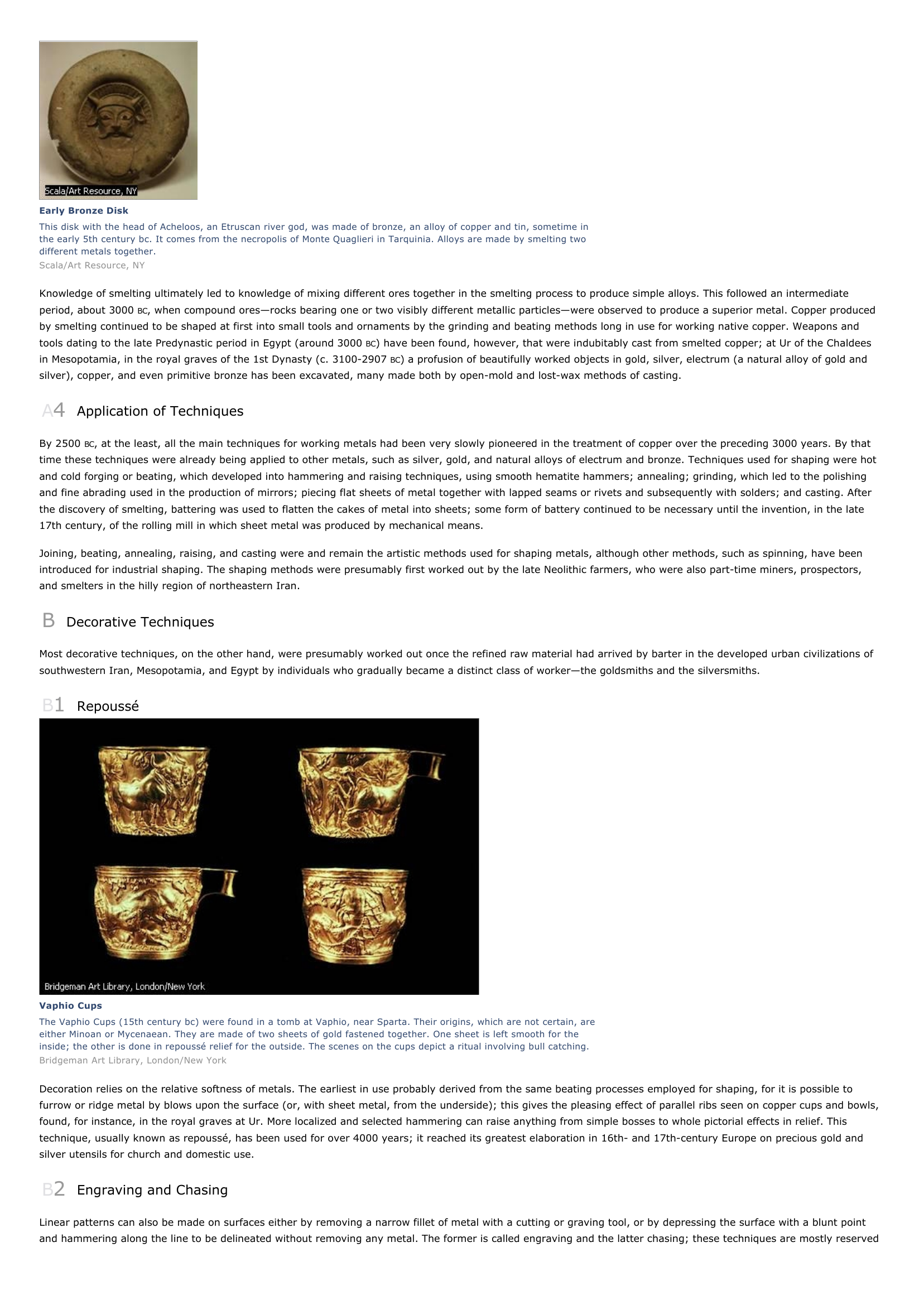

Metalwork I INTRODUCTION Metalwork, in the fine arts, objects of artistic, decorative, and utilitarian value made of one or more kinds of metal--from precious to base--fashioned by either casting, hammering, or joining or a combination of these techniques. II ORIGINS OF METALWORK Metals have been used throughout recorded history for fine and decorative art. By the 1st century AD the metals in prime use today--iron, copper, tin, lead, gold, and silver--already had a long development that had begun some 10,000 years earlier with the working of copper. The distinction between precious metals (gold, silver, and--since the 18th century--platinum) and base metals (iron, copper, tin, and lead) dates from the ancient civilizations of the Middle East and prehistoric Europe. Gold and silver, sacred to worshipers of the sun and the moon, were at first reserved for ritual religious use, temple objects, and the jewelry and ceremonial accoutrements of semisacred figures such as the early Egyptian pharaohs, the Middle Eastern priest-kings, and the tribal chieftains of Europe from Spain to the Caucasus. As these rare materials became more plentiful, they proclaimed the status of a wider group, the elite in each society--its nobility and great warriors. The use of gold and silver was extended to personal adornment, to personal belongings, such as eating and drinking utensils, weapons and equipment, and even to such furnishings as mirrors, lighting stands, chairs, and beds. Gold and silver gradually acquired a quantitative value, which was ultimately expressed in the first coins, stamped gold and silver disks issued by the Lydians in Asia Minor during the early 7th century BC. The notion of coinage soon spread throughout the Middle East and into Greece, and ever since that time coins have retained the notion of beauty as well as value. The base metals iron and bronze were appreciated for their strength, especially for weapons and tools; copper, tin, and lead came to be used mainly for their utility or durability--for cooking, for storage, or for strengthening wooden constructions of many kinds. The particular property of metals--that they can be mixed or alloyed in various combinations and proportions to make better materials for particular purposes--was understood in the ancient world. Copper and tin produced bronze; lead and tin produced pewter. This property has been exploited with ingenuity and increasing scientific knowledge in the past 2000 years; thus, while the designations iron, copper, lead, silver, and gold are still commonly used, nearly every metallic product is, in fact, a highly complex and carefully formulated alloy. For the purposes of the fine and decorative arts, however, metals have been used either in their simple state or in uncomplicated alloys. III CHARACTERISTICS OF METALWORK All metals share certain characteristics: a uniform smooth complexion; great strength and tenacity, but also easily worked surfaces; and malleability (their capacity to assume any desired shape). This inherent malleability of metals is exploited by pressure in its solid state or by molding when it is liquefied by heat. In addition, metals were the first reusable materials known (unlike stone, shell, or wood), since broken or obsolete metal objects can be melted down and the substance reused. This relative permanence came to be appreciated after the discovery of smelting in about the middle of the 5th millennium IV BC. TECHNIQUES OF METALWORK The techniques of working metal developed very slowly and for long only in connection with the progress of metallurgy itself--the mining of a mass of metal from the earth. Scholarly opinion now holds that the first steps were taken after the adoption of settled ways of life--represented by agriculture and stock breeding--in northeastern Iran, the first area in which this occurred. In this area were native copper, metal-bearing rocks, malachite, and abundant timber, which allowed a steady progress of discoveries to be made. The Iranians learned the essentials of metalworking by using native copper; variations of the techniques were applied to other metals as they were recognized. A diffusionist theory is now generally accepted: The techniques were developed in northeastern Iran, but the products, and possibly also the producers, gradually were carried by trade and emigration to other areas. They went to the valley civilizations of Mesopotamia, across western Persia and through the east Mediterranean littoral to Egypt, across North Africa, and on into Spain. A second route lay from western Iran into Anatolia and then across the Hellespont to Europe. This diffusion began in about the 5th millennium A BC and was continued for over 2000 years. Early Techniques The earliest metalworking was of copper, perhaps as early as the 11th millennium, using small nuggets of native copper picked up in streams or from the ground. These nuggets were presumably at first considered a special kind of attractively colored stone, and by grinding and beating--methods already used for working stones, flints, and obsidian--they could be shaped into ornaments. A1 Annealing The next step was the discovery, about 5000 BC, that these special stones could be worked on with repeated hammering if the mass was heated to a full red color and cooled from time to time, and that this kept the metal soft and workable. Ordinary wood fires produced sufficient heat for this process, called annealing. Repeated hammering without annealing will cause the metal to become too hard and brittle, with resultant jagged cracks. A2 Smelting The next discovery came after the development of the closed two-chamber pottery kiln, which produced a far greater heat than the open fires adequate for the earlier low-fired pottery. This took place probably before 4000 BC and led, after some 500 years or so, to the smelting first of small pieces of native copper, malachite (which under certain conditions will render into copper), and finally large amounts of copper ores, in furnaces that initially resembled the two-chamber pottery kilns. It was not until copper ores were smelted that any significant increase in the supply of copper and copper products could take place. A3 Alloys Early Bronze Disk This disk with the head of Acheloos, an Etruscan river god, was made of bronze, an alloy of copper and tin, sometime in the early 5th century bc. It comes from the necropolis of Monte Quaglieri in Tarquinia. Alloys are made by smelting two different metals together. Scala/Art Resource, NY Knowledge of smelting ultimately led to knowledge of mixing different ores together in the smelting process to produce simple alloys. This followed an intermediate period, about 3000 BC, when compound ores--rocks bearing one or two visibly different metallic particles--were observed to produce a superior metal. Copper produced by smelting continued to be shaped at first into small tools and ornaments by the grinding and beating methods long in use for working native copper. Weapons and tools dating to the late Predynastic period in Egypt (around 3000 BC) have been found, however, that were indubitably cast from smelted copper; at Ur of the Chaldees in Mesopotamia, in the royal graves of the 1st Dynasty (c. 3100-2907 BC) a profusion of beautifully worked objects in gold, silver, electrum (a natural alloy of gold and silver), copper, and even primitive bronze has been excavated, many made both by open-mold and lost-wax methods of casting. A4 Application of Techniques By 2500 BC, at the least, all the main techniques for working metals had been very slowly pioneered in the treatment of copper over the preceding 3000 years. By that time these techniques were already being applied to other metals, such as silver, gold, and natural alloys of electrum and bronze. Techniques used for shaping were hot and cold forging or beating, which developed into hammering and raising techniques, using smooth hematite hammers; annealing; grinding, which led to the polishing and fine abrading used in the production of mirrors; piecing flat sheets of metal together with lapped seams or rivets and subsequently with solders; and casting. After the discovery of smelting, battering was used to flatten the cakes of metal into sheets; some form of battery continued to be necessary until the invention, in the late 17th century, of the rolling mill in which sheet metal was produced by mechanical means. Joining, beating, annealing, raising, and casting were and remain the artistic methods used for shaping metals, although other methods, such as spinning, have been introduced for industrial shaping. The shaping methods were presumably first worked out by the late Neolithic farmers, who were also part-time miners, prospectors, and smelters in the hilly region of northeastern Iran. B Decorative Techniques Most decorative techniques, on the other hand, were presumably worked out once the refined raw material had arrived by barter in the developed urban civilizations of southwestern Iran, Mesopotamia, and Egypt by individuals who gradually became a distinct class of worker--the goldsmiths and the silversmiths. B1 Repoussé Vaphio Cups The Vaphio Cups (15th century bc) were found in a tomb at Vaphio, near Sparta. Their origins, which are not certain, are either Minoan or Mycenaean. They are made of two sheets of gold fastened together. One sheet is left smooth for the inside; the other is done in repoussé relief for the outside. The scenes on the cups depict a ritual involving bull catching. Bridgeman Art Library, London/New York Decoration relies on the relative softness of metals. The earliest in use probably derived from the same beating processes employed for shaping, for it is possible to furrow or ridge metal by blows upon the surface (or, with sheet metal, from the underside); this gives the pleasing effect of parallel ribs seen on copper cups and bowls, found, for instance, in the royal graves at Ur. More localized and selected hammering can raise anything from simple bosses to whole pictorial effects in relief. This technique, usually known as repoussé, has been used for over 4000 years; it reached its greatest elaboration in 16th- and 17th-century Europe on precious gold and silver utensils for church and domestic use. B2 Engraving and Chasing Linear patterns can also be made on surfaces either by removing a narrow fillet of metal with a cutting or graving tool, or by depressing the surface with a blunt point and hammering along the line to be delineated without removing any metal. The former is called engraving and the latter chasing; these techniques are mostly reserved for precious metals. B3 Matting, Etching, and Oxidization Another method of surface decoration is to impress it with repeating patterns of hatched lines (again, usually used on precious metals), thus matting or breaking up areas to contrast with other areas left polished and reflective. Yet another method of darkening selected areas is to etch them with acid, a technique mostly used on steel armor and the steel parts of weapons. In the 19th century a process called oxidization was devised; with it, a subtle darkening effect was achieved on polished silver surfaces with a pickling process using sulfur. B4 Gilding and Inlay Luxurious decorative effects may be achieved by applying one metal to another or by inlaying a precious metal into a less precious one. Such, for instance, are the techniques of gilding or parcel-gilding silver, bronze, and steel objects and of inlaying silver and gold wires into brass and bronze. The latter was perfected in the Arab world in the Middle Ages; it is called damascening, after Damascus, a Syrian city particularly famous for such work. In the 1st millennium BC, Chinese ceremonial bronze vessels were exquisitely inlaid with gold and silver. B5 Granulation and Filigree Other surface decoration techniques using metal on metal are granulation and filigree. Granulation, used for jewelry, is only possible with gold. In granulation, beads of gold are soldered onto gold surfaces; the finest of this work was produced by the Etruscans in the 6th and 5th centuries BC. The beads were so minute as to give the appearance of a bloom to the gold surface, rather than of a beaded surface. Filigree can be made of both gold and silver; openwork patterns are worked from minute cables made of two or three twined or braided gold or silver wires. Filigree was extremely popular in the 16th and 17th centuries to decorate vases and drinking vessels, especially in Italy and Germany, as well as in 18th- and 19th-century South America. In Russian and Scandinavian countries filigree has survived as a provincial craft and is used for boxes, mirror cases, and peasant jewelry. It is obviously fragile work and, except for jewelry, usually has a backing material. Similar openwork effects are called ajouré, mostly used to ornament domestic silver and some jewelry, and are achieved by cutting or piercing patterns in the metal. Ajouré was most popular from the late 17th to the early 19th century. Conversely, raised patterns can be made by soldering small castings or cutout motifs onto a flat surface, a method of decoration in use for over 4000 years. B6 Embellishment with Other Materials Frankish Jewelry These two fibulae, or decorative pins, from the 6th century were used to fasten clothing. They are about 10 cm (4 in) long, made of gold and bronze, and decorated with garnets and niello work. They were originally found in the Charente area in France and are now part of the collection of the British Museum, London. Bridgeman Art Library, London/New York Every civilization with a wealthy or high-status class has, for over four millennia, used decorative metalwork embellished with other materials. These include precious and semiprecious gemstones, enamels (including niello, a black finish), a variety of exotic substances such as rare woods, ivory, jade, and amber, and reverse-painted and gilded glass (verre églomisé). In ancient times ceremonial furnishings were almost as exotically decorated as personal jewelry and cult implements. In more recent times this type of decorative metalwork has tended to be reserved for personal objects, including jewelry. C Metalwork as Art In considering the use of metals in art, it must be remembered that only since the Industrial Revolution has a clear distinction been made between machine-made useful objects and handcrafted fine and decorative art objects. For thousands of years, until the mid-18th century, everything was of necessity handmade; useful objects were almost always shaped and decorated to have aesthetic appeal, although pieces that might now be considered purely fine art--such as statues and jewelry--served deeply serious religious or ceremonial functions. V TYPES OF METALWORK The shape, function, and appearance of metalwork are determined in large part by the type of metal used. The precious metals (gold and silver) share these characteristics; the base metals (copper, tin, lead, and iron) and their alloys (bronze, brass, and pewter) may differ widely in their characteristics. In metalwork of the Renaissance and after, however, these characteristics may overlap; this happened, for instance, when wrought iron was worked with exquisite refinement in 17th- and 18th-century Europe. A Gold Gold dust and small gold nuggets are found in many areas of the earth, either on the surface of the land or in streams and shallow rivers. Presumably, its beauty of color and relative softness made it attractive for ornament or for religious purposes from primeval times. A1 Gold in the Ancient World Death Mask of Tutankhamun The death mask of Egyptian pharaoh Tutankhamun is made of gold inlaid with colored glass and semiprecious stone. The mask comes from the innermost mummy case in the pharaoh's tomb, and stands 54 cm (21 in) high. Bridgeman Art Library, London/New York The earliest formed gold objects, however, are small beads found in prehistoric graves in Egypt, which may date from before the 6th millennium BC. Gold was plentiful in Egypt's desert areas between the border of cultivation on the east bank of the Nile and the Red Sea and also to the south of Egypt in Nubia. A rather comprehensive picture of Egyptian goldwork over the 4000 years of its history has been obtained through the excavation of many sites during the past 200 years. Gold was reserved for the use of the kings in the Old Kingdom (2575-2134 BC) and for the nobility and priesthood in later periods. It was used for jewelry, including head ornaments, large pectorals (collar necklaces), rings, earrings, and bracelets, and special funerary equipment, including all of the above as well as toe- and finger-guards and ceremonial sandals. Gold was also used for the decoration of insignia of kingly power--the flail, the scepter, and the throne--as well as for drinking cups and such personal weapons as daggers. The solid gold coffin (1323? BC, Egyptian Museum, Cairo) discovered (1922) in the tomb of the pharaoh Tutankhamun and weighing 1128.5 kg (2448 lb) is proof of the abundance of gold available by the time of the 18th dynasty. The Romans who made contact with Egypt under Cleopatra in the 1st century BC were amazed at her wealth, represented by quantities of gold utensils and ornaments and by the plethora of luxury crafts practiced at Alexandria, including perfumery, elaborate glassblowing and glass cutting, and, of course, goldsmith's work. When Egypt became a Roman province, many of these luxury arts were carried to Rome and especially to Pompeii by migrating craftsmen. Scythian Metalwork Scythian animal sculptures are often a fine blend of abstraction and lifelike representation. Scythian craftsworkers frequently used the figure of a panther, as in this emblem from a Scythian shield, now in the Hermitage Museum in Saint Petersburg, Russia. The figure dates from the 7th century bc and is made of gold, amber, and colored enamel. Hermitage, St. Petersburg, Russia/Bridgeman Art Library, London/New York The use of gold in the ancient Mesopotamian civilizations of Sumer, Babylon, and Assyria and later those of Syria and Persia (present-day Iran), as well as the succeeding powers in Anatolia and Greece, paralleled that of Egypt, although each culture had its own distinct artistic style. Gold was also owned by the great chieftains of the nomadic Scythian tribes who roamed areas stretching from the lower Danube basin in Europe to eastern Kazakhstan in Central Asia. Through their trading contacts with settled peoples to the south, they obtained a great deal of gold that was elaborately worked into large ornaments--such as neck torques--and such personal objects as drinking bowls and daggers. A2 European Gold Crown of the Holy Roman Emperor The imperial crown of the Holy Roman Empire is a masterpiece of goldsmith's art from the 11th century, when it was first used at the coronation of Conrad II. The crown is made of eight arched pieces of gold (two large and six small) that are decorated with pearls, precious stones, and enamel. Conrad was crowned by the pope in 1027. The crown is in the Art History Museum in Vienna, Austria. Kunsthistorisches Museum, Vienna, Austria/Bridgeman Art Library, London/New York The restrictive use of gold practiced in the ancient world was continued in the Roman and subsequent Byzantine empires and in the European kingdoms that were their successors; the same restrictions on its use were perpetuated in the European colonies and settlements that were to become the modern sovereign states in North and South America, South Africa, and Australia. It is still reserved for religious objects, state regalia--especially crowns, scepters and seals--for marriage rings and personal jewelry, and for prizes and trophies. Saltcellar of Francis I Florentine sculptor Benvenuto Cellini's saltcellar, commissioned by King Francis I of France, is an example of goldwork with enamel. It is 26 by 33.3 cm (10.25 by 13.1 in). The figures represent water and earth, according to Cellini's Autobiography. The piece is now in the collection of the Kunsthistorisches Museum, Vienna, Austria. Bridgeman Art Library, London/New York Gold still commands a deep, almost reverent respect. The great enameled gold salt (1540-1543, Kunsthistorisches Museum, Vienna) wrought by Benvenuto Cellini for Francis I of France was not an egregious use of the metal, for at the time salt was still considered a precious commodity of almost mystical importance. Where it was impractical to make domestic pieces in solid gold--such as drinking cups, which would be too heavy and too easily scratched or dented--it was common practice in Europe for many centuries to gild silver vessels. Kings, princes, and religious or civil potentates, however, might still use pure gold pieces, such as cups or chalices, on high ceremonial occasions. A3 Gold in Africa and the New World Similar restrictions were observed in the seaboard kingdoms of West Africa contacted by the exploring Portuguese in the 15th century. Gold was reserved for the use of chieftains and nobility, not so much for reasons of vanity or self-importance, but because its mystical attraction and power should only be available to a consecrated individual or an elite caste. The Spanish conquerors of Mexico and the South American empires were amazed at the superabundance of gold, as well as the absence of greed in its owners. Gold was used for religious and ceremonial artifacts, often of great size and solidity, but it was its color--in these sun-worshiping cultures--that was prized, not its monetary or bargaining value. The German Renaissance master Albrecht Dürer, who saw gold and other treasures from the New World during his stay in Antwerp in 1521, was particularly struck by the unusual forms and artistry of the goldwork; he recorded his appreciation of their beauty, even though they were wrought in an artistic idiom that was totally alien to European art. A4 Chinese Gold Silk merchants of the Earlier Han dynasty (206 BC-AD 220) required payment in gold from the intermediaries catering to the Roman luxury trade. Apparently, the Chinese were reluctant to disturb the earth's spirits by mining. Gold was used in small quantities--mostly for inlay--in the late Zhou (Chou) period (c. 500-250 BC), which probably came from native gold nuggets. Whenever contacts with the West were maintained, however, large amounts of both silver and gold reached China and were wrought with characteristic refinement. The periods of contact were the Han, Tang (T'ang), late Yuan (Yüan), Ming, and Qing (Ch'ing) dynasties. Goldwork of the Han dynasty is especially fine; it included granulation, learned from Western models, and lost-wax castings (see Cire Perdue), a technique long practiced in China for bronzes. Most characteristic of the Ming period are the delicate openwork head ornaments and tiaras, often decorated with filigree and with jewels held on wires that trembled as the wearer moved. B Silver In the region called Pontus in ancient times, fronting the southern coast of the Black Sea of what is now eastern Turkey, silver began to be produced by smelting galena, an ore containing lead with a small proportion of silver. This development was subsequent to the first smelting of copper ores farther to the east; it may, however, have followed quite close upon it, for galena ore sparkles with visible promise. Migrating copper smelters may have been the first to recognize its metallic potential. The discovery that lead ultimately will burn away during a protracted roasting, leaving a small globule of silver, was probably accidental. B1 Silver in the Ancient World The deliberate extraction of silver from lead was apparently mastered by the end of the 3rd millennium BC. Found in the royal graves at Ur were silver objects containing varying proportions of lead, fashioned with the same techniques used for gold and copper. In the Sumerian and succeeding civilizations in the Middle East, silver was restricted to the same uses and classes as gold. In the 2nd millennium, however, it was also allotted by temple priests to certain merchants for buying larger quantities of copper abroad, and small pieces of silver in standard weights came to have a set value. Coinage was a final step in this process. Silver remained a restricted material until the late Roman Republic (to 27 BC) when the huge quantities of silver available to Rome made it a vehicle for trade, wealth, and the ostentation of wealth. Many classes in the Roman Empire, including wealthy freed slaves, might own cups, spoons, wine vessels, even tables and bathtubs in solid silver, often elaborately ornamented with repoussé and cast decoration. B2 European Silver Silver Teapot and Stand This silver teapot with stand was designed by Hester Bateman in 1790, London. The handle is made of carved wood, and the piece is carefully crafted. The design, which is simple and formal, features neoclassical detailing. Bridgeman Art Library, London/New York During the early Middle Ages in Europe, silver was in short supply, although many of the early kingdoms minted a silver currency; chalices, gospel covers, and other liturgical equipment were customarily provided for church use. Silver mines in Austria and Germany provided most of the new silver of the Middle Ages, augmented after about 1550 by silver coming from Spanish mines in South America. Silver became available for large issues of currency and ultimately for private ownership in the form of reserved coins or a great variety of domestic utensils. Silver spoons or silver-edged wooden drinking bowls were modest items an individual might own, but wealthier persons would hold and express much of their reserve capital in salts, serving dishes, plates, beakers, and elaborate covered cups. By the 17th century in Europe, the notion of table silver had taken a firm hold, and for a brief period toward the end of the century, silver lighting fixtures, orange-tree tubs, and silvermounted furniture were so popular that a scarcity of silver resulted. Silver thereafter came to be restricted generally to eating and drinking utensils; in the 19th century, silver serving pieces such as tureens, tea and coffee sets, candlesticks, and centerpieces became popular. In the modern era, even these tend to be of silver substitutes such as stainless steel or of silver-plated base metals, since nearly all mined silver is consumed in industrial processes. Silver was also used by European artists for religious and secular statues, figures, and ornaments for many centuries. Today, silver is once again being used for individual works by a growing number of silversmiths. B3 Chinese Silver In the Far East, during the Tang dynasty in China and again after unbroken contact with the West was established in the 16th century, trade goods were sold for European bullion or coinage, and good use was made of this windfall of precious metal. The silver cups, bowls, and dishes of the Tang dynasty in particular were worked with engraved and gold-leaf designs of outstanding beauty. C Bronze The production of bronze by mixing copper and tin was an established practice by about 1500 BC throughout the Eurasian landmass. The small amounts of primitive bronze found in the early Sumerian graves probably resulted from the smelting of relatively rare naturally mixed ores. Tin and copper ores, however, were plentiful in Europe; most authorities agree that, although copper smelting was widely practiced (presumably through contacts with the Middle East), by the end of the 3rd millennium BC tin ores and copper ores were being smelted together to produce what was recognized as a superior form of copper--more fluid when hot and harder when cold. Bronze was easier to cast than copper and produced better tools and weapons. A refinement of the mixing method soon developed, in which tin and copper were smelted separately and were then melted together in controlled proportions. Trade contacts brought European tin eastward. C1 Bronze in the Ancient World In both Europe and the Middle East, bronze was mainly used for weapons and cutting tools--swords, spears, arrowheads, shields, adzes, and axes--although bowls and cauldrons were also made from bronze. During the 1st millennium, bronze was especially prized in Greece and later in Rome for sumptuous and elegant furnishings, such as tripods, bed and table frames, small oil lamps, and tall lampstands, often elaborately decorated with raised animal or leaf decoration. C2 Chinese Bronzes Bronze Vessel of the Shang Dynasty The Bronze Age culture of the Shang dynasty (1570?-1045? bc) in China developed a sophisticated metallurgy industry that produced large numbers of bronze ritual vessels. The intricate designs were achieved through the piece-mold casting process, in which molten bronze was poured into clay molds that contained impressions of the desired design. THE BETTMANN ARCHIVE/Corbis In China bronze appears to have been used almost exclusively for bells, mirrors, and vessels in a variety of prescribed forms for distinct functions in religious rites, as well as for weapons and for the decoration of horse trappings and chariots. This first Bronze Age in China lasted from about 1800 206 BC). BC to the end of the Qin dynasty (221- The bronze ritual vessels are especially admired for the nobility of their forms and the vigor of their abstract linear decoration. The decoration consists of highly conventionalized and attenuated masks and mythical monster forms, such as dragons. These vessels were cast from molds prepared with the decoration cut and incised on the inner face, resulting in equivalent projections on the cast vessel. C3 European Bronzes Panel From the Gates of Paradise This is a portion of one of the ten panels designed by the Italian Renaissance artist Lorenzo Ghiberti between 1425 and 1452 for the east doors of the baptistery of the Florence Cathedral. This panel tells the story of Joseph in Egypt from the Bible. The doors, made of gilt bronze, were known as the Gates of Paradise. Their style was influenced by classical Roman art. Scala/Art Resource, NY After bronze was superseded by iron for weapons, it remained in use in Europe as an artist's medium. Greek bronze statues, vases, and wine vessels, sometimes of large size and elaborately gilded, were greatly admired in Rome. The wandering tribes who gradually superseded Roman power in Europe (including Italy), also appreciated bronze, but used it more often for portable items such as shields and bowls as well as for buckles and brooches (often inlaid with colored stones or opaque enamel). In church furnishings, bronze continued to be used for larger pieces, such as candlesticks, baptismal fonts, and coffers. Perhaps the most famous bronze sculptures of the Renaissance are Lorenzo Ghiberti's sumptuously ornamental gilded bronze doors--the Gates of Paradise (1425-1452)--for the Baptistery at Florence, consisting of ten self-contained rectangular panels of biblical scenes cast in high relief. Many other Renaissance artists used this medium for smaller cast figure sculptures, often inspired by antique works of the classical era; this prime use for bronze has persisted to the present day. In the 18th and 19th centuries, and especially in France, gilt bronze attachments--called ormolu--in the form of projecting and richly decorated cast mounts on edgings, drawers, and feet, were added to luxury furniture. C4 African Bronzes In Nigeria, between the 14th and 16th centuries, cast bronze sculptures of extreme refinement were made at Benin in a highly developed artistic convention unrelated to European styles. D Copper A large statue (c. 2300 BC, Egyptian Museum, Cairo) of the 6th-dynasty king Pepi I (reigned about 2289-2255 BC), made from hammered sheet copper, provides evidence that copper may have been more extensively used for fine art than is commonly supposed. D1 Copper in the Ancient World In Egypt and elsewhere in the ancient world, copper was superseded for weapons and tools by bronze and quickly became relegated to the realm of a useful metal for dishes, cups, and light domestic utensils. It was important, however, as the necessary ingredient for bronze and later as a toughener for silver and gold, although added in small proportions (sterling has 7.5 percent copper). D2 European Copper and Brass Copper was also important as the base for champlevé enamel plaques in the Middle Ages and later, for its softness facilitated the excavation of small areas to be filled with colored glass pastes. Copper is an ingredient, with zinc, of brass. In the Middle Ages in the town of Dinant (now in Belgium), large brass dishes with raised decoration were produced and exported in considerable quantities, although the Netherlands was the most prolific producer of brasswares. Brass was similarly used in the Islamic East for large dishes and braziers. Eastern craftsmen who settled in Venice in the 15th century produced exceptionally well-wrought bowls, ewers, dishes, and candlesticks damascened with elaborate oriental decoration in gold and silver; their method was continued by Venetian artisans using Renaissance styles of decoration after the middle of the 16th century. Large brass chandeliers designed to hold numerous candles were made in the Netherlands and England in the 17th century and were to be found in the early colonial homes in North America in the 18th century; brass drawer pulls were also popular on furniture in the colonies. Brass has survived into the 20th century in the form of such fixtures as door knockers, doorsills, letter boxes, candlesticks, and andirons. E Lead and Pewter The Romans, who had a superabundance of lead from their silver-refining activities, used lead primarily for utilitarian purposes--roofs, coffins, water cisterns, conduits, and plumbing. E1 Lead Lead is exceptionally soft and easily worked and was used in the Middle Ages in Europe for external architectural decoration. In England it was used extensively for the pipeheads of rainwater guttering and for roof coverings. From the 12th to the 15th century, lead baptismal fonts with cast raised decoration were produced. In the 17th century, lead garden statues became popular and remained in favor into the 18th century. During the 16th century, cast lead plaquettes were made in Germany by goldsmiths and silversmiths who specialized in supplying designs to other goldsmiths; they exported these plaquettes of the latest designs--both abstract and pictorial--to many parts of Europe. These plaquettes, which reproduced faithfully all the details of the carved-wood or soft-stone originals, are now collected as works of art in their own right. E2 Pewter Pewter Bleeding Bowl This pewter bleeding bowl was made in France in the 16th century. The face on the bowl may be its original owner; the designer is unknown. The rather crude design work was incised into the metal, and the face and crown are probably cast pieces attached to the bowl. Bridgeman Art Library, London/New York Tin was available to the Romans both from their possessions in the Iberian Peninsula and in the British Isles. It was an important ingredient in bronze, but when mixed with lead (first in the 3rd century AD ) it produced the first pewter. A few hundred pieces of Roman pewter, however, are all that remain. No other early pewter, from Roman times until the 14th century, is known, except for the chalices and patens found in priests' tombs at Metz, France. Pewter, however, was probably made in some quantity. Churches too poor to own silver communion plates were allowed to use pewter after the 11th century; it was a flourishing craft when it came to be regulated in the 14th century in England. Pewter was commonly used for the eating and drinking vessels of the lower classes all over Europe, except in Spain. The metal is silvercolored when new and dulls to a pleasing, lustrous gray. In form, it was made in the usual shapes for pottery or silver and tended to rely on proportion and appropriateness rather than on decoration for its appeal. Some pewter, however, was decorated in the 16th and 17th centuries with cast motifs, particularly on the lids and handles of tankards; in Germany, Switzerland, and Scandinavia incised decoration or undulating lines made with a wheel were popular. American pewter is highly prized by collectors for its amplitude and dignity, as well as for its connection with the country's early history. Dates and the initials of the owners are often found on it. Old pewter is comparatively rare, for it was the established practice everywhere to take old or deformed pieces back to the pewterer as part payment toward new purchases. Pewter was largely supplanted by silvered base metals in the 19th century, although it has reappeared in the present century for household items such as tankards and flatware. F Iron Small pieces of jewelry of meteoric iron have been found in Egyptian tombs, and no doubt the metal was for long treasured as an occasional find. The Hittites of Anatolia, however, appear to have been the first (c. 1400 BC) to understand and control the production of iron from its ores. This gave them a temporary military advantage over their neighbors in the superior weapons they made from iron. For such a versatile, functional, and strong metal, iron has had a surprisingly consistent history of use for artistic and decorative purposes. The Chinese were the first to cast iron; from the 6th century AD they used cast-iron supports for buildings and for multistory pagodas. In Europe, iron was wrought--that is, hammered into shape when hot--by a special group of workers now called blacksmiths. Blacksmiths wrought coffers and weapons and made such large items of furnishings as great knockers and ring handles for the immense doors of castles and cathedrals as well as beautifully scrolled bands for strengthening doors. Wrought-iron railings, with superbly detailed work that looks almost like lace from a distance, was popular in the 17th and 18th centuries. Steel armor was often highly decorative, with splendid engraved or acid-etched motifs in the 16th century. The armorers who wrought them used a steel derived from iron and employed many of the hot forging techniques that were pioneered by blacksmiths over the centuries. After the Arts and Crafts movement was introduced in the mid-19th century, some exceptional wrought-iron work was produced in England. Cast iron appears to have been introduced into Europe from knowledge of the Chinese success with it. For a long time, it had few artistic uses, although the cast firebacks introduced in the 15th century remained popular for some 200 years. In Germany, Switzerland, Scandinavia, and the Netherlands, cast rectangular plates for wood-burning, enclosed stoves were also made, often decorated in relief at the moment of their casting from prepared molds with pictorial or abstract ornament. Toward the end of the 18th century, wrought iron began to be replaced by less costly cast iron for railings, balconies, banisters, and for garden furniture and decorations; this manufactured work, once considered as intrinsically bad and devoid of artistic merit, has come to have a certain appeal to present-day collectors. See also Bell; Coins and Coin Collecting; Crown; Enamel; Flatware; Inlay; Jewelry; Sculpture; Sword Contributed By: Jessie McNab Microsoft ® Encarta ® 2009. © 1993-2008 Microsoft Corporation. All rights reserved.